Address: 4545 Futuro Ct., Dubuque, Iowa

Phone: 563-583-5125

Website: Uelnertool.com

Hours: Monday-Friday: 7 a.m. to 5 p.m.; Saturday: 7 a.m. to noon

During the course of more than seven decades, a family-owned Dubuque business has established itself as a reputable designer of industrial manufacturing tools and producer of individual parts.

Uelner Precision Tools & Dies, 4545 Futuro Court, is celebrating its 75th anniversary this year.

“We have customers throughout the United States, and we are shipping parts all around the world,” said company President Thomas Uelner. “We have some local business, but a lot of it is outside of the area.”

There are two major facets to the operation of the company. First, it designs and creates the tools needed to manufacture specific mechanical parts, whether interior automotive components or agricultural parts.

Thomas Uelner said these tools are complex and require a precise design in order to work properly.

“These can take six months to build and have 500 components that go into it,” Uelner said. “A lot of skill goes into making that kind of tool.”

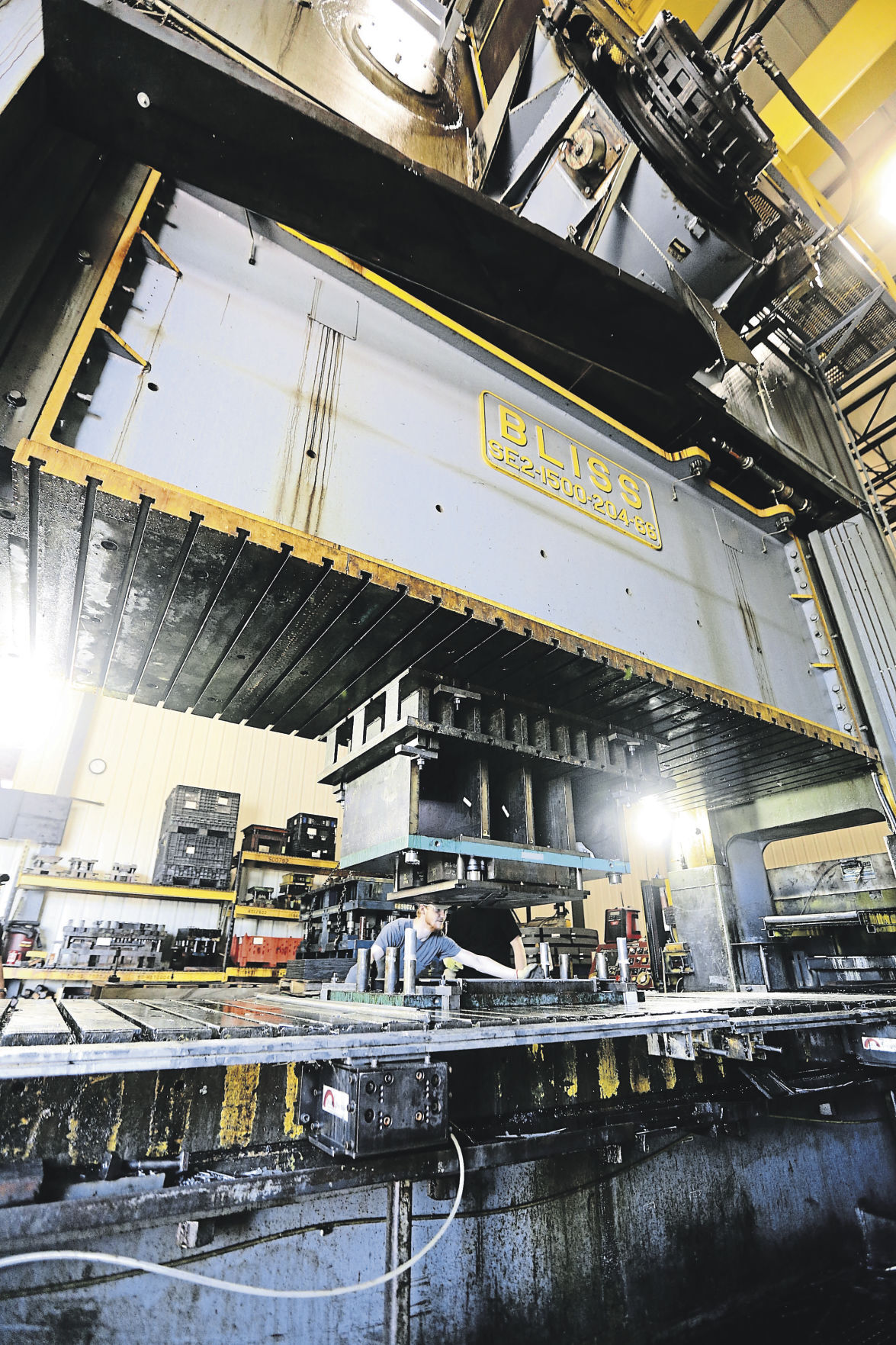

Secondly, the company uses its metal stamping presses to manufacture a variety of parts for customers, such as automotive parts.

Brad Kueter, head of continuous improvement and sales and marketing, said Uelner’s 55,000-square-foot facility produces from 9 million to 14 million parts per year for companies that include the General Motors Co., Tesla and Magna International.

“For one customer, I am making 25,000 parts a week,” Kueter said. “When you add up all the customers we serve, that is a lot of parts.”

The company was founded in Dubuque by Thomas Uelner’s grandfather Felix in 1946.

Initially, Felix ran the company out of a rented garage near Flora Park. At the time, the company specifically focused on tool and die production. It eventually moved to a more permanent location on Washington Street.

Early on, Thomas Uelner said, the company primarily created the tools needed for toy production.

In 1986, the company moved to the Dubuque Industrial Center West in a new facility.

In 1997, the company, by then under the leadership of Thomas, invested in adding production stamping to its operations. Today, the company has evolved from a small tool shop with a handful of employees to a major tool and die provider in the Midwest region that employs nearly 50 people.

Jayne Uelner, the wife of Thomas and the director of human resources for the company, said Uelner Precision Tools & Dies has made a name for itself through its commitment to creating quality parts, something that is particularly important during a time when some companies are turning to having their tools produced overseas.

“It’s all about the quality and the skill of the people that you hire and are working with,” she said.

Thomas said many companies often experience issues with delivery and quality when outsourcing their tool production, which, in turn, gives his company the opportunity to make things right.

“With Ford and GM, we kept them from shutting down because of a poorly made part offshore,” Thomas said. “We were able to improve the tool enough that we could take it to their facility and run it in their presses.”

However, Thomas also attributed the company’s continued success to its investment in quality employees. The company participates in promoting trade school education, and those that it hires are given competitive pay and workplace flexibility.

“It’s the people that you hire, and the people that grow every day that make the company better,” Thomas said. “This is a family business. It’s not just about pushing numbers.”

Though the company faces challenges, ranging from workforce shortages to a transition from in-person to online sales methods, Thomas said he feels confident in the future of his now-historic family business.

“It’s really rewarding,” he said. “Seeing our employees and our company grow is a rewarding thing to see.”