For many businesses in the tri-state area, buying a computer has become a much lengthier and expensive process.

Kendall Hunt Publishing, headquartered in Dubuque, purchases three or four computers per week for its employees. What previously cost about $600 per model now is costing $800. What used to take a few days to ship now takes up to three to four weeks.

“We’re seeing a price increase, and we’re seeing a delay in availability,” said Chris Reichling, chief information officer for the company. “The company has been absorbing those costs. We’re an educational business, so we don’t have the ability to turn that around and pass those costs along to the customers.”

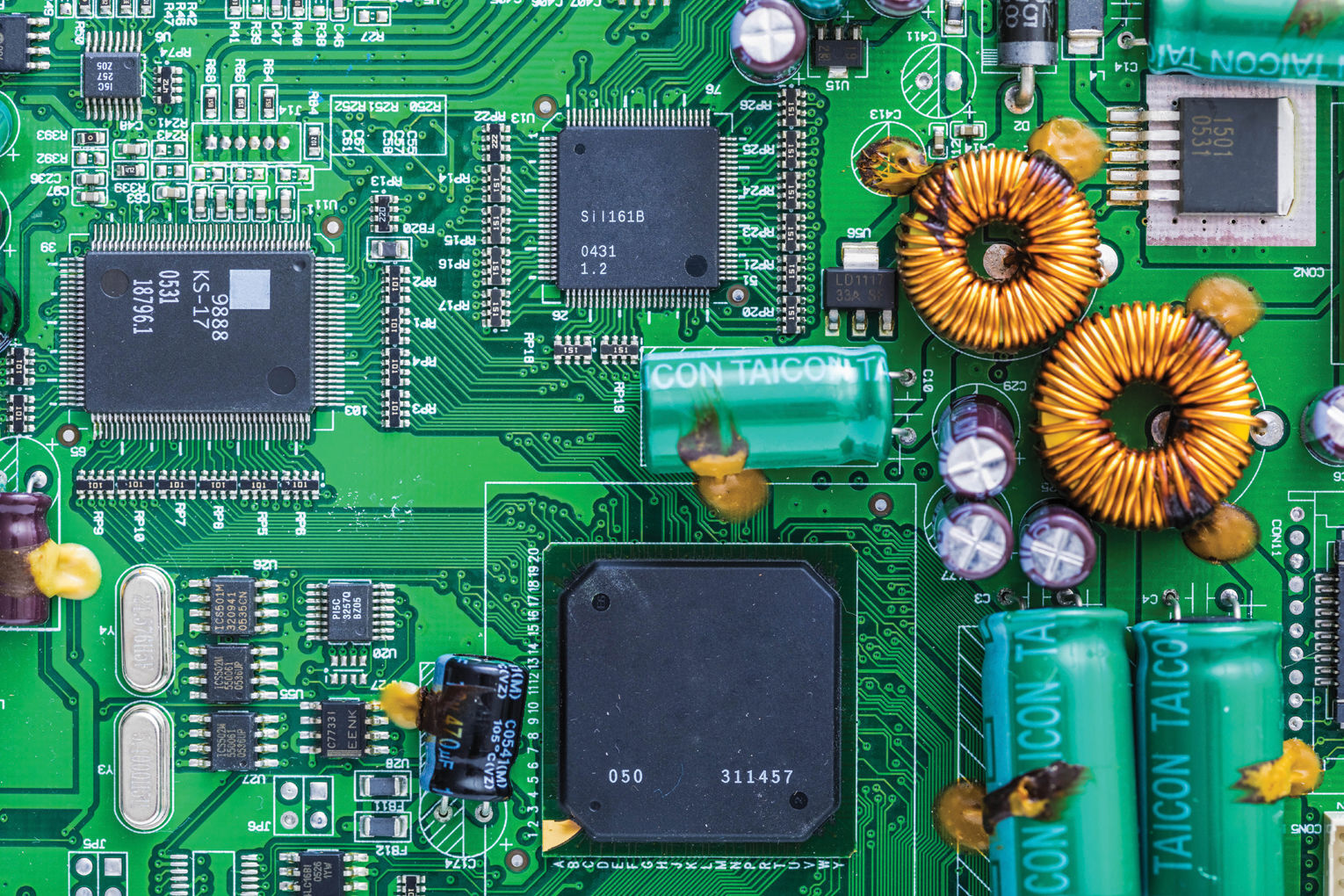

For months, computers and other electronics have risen in price and shrunk in available supply, all a result of a global shortage in computer chips, which are required for the production of laptops and desktop computers.

The COVID-19 pandemic caused widespread disruption to manufacturing and shipping in many industries throughout the world, but the production of computer chips was particularly hampered and the mass quarantining of much of the global population, leading many people to work or study from home, caused a surge in demand for home products that require computer chips, including computers, video game consoles and tablets.

In June 2021, worldwide sales of semiconductors, an essential component for the production of computer chips, reached 44.5 billion, an increase of 29.2% from June 2020, according to the Semiconductor Industry Association.

With manufacturers unable to keep up with demand, electronics manufacturers have begun raising prices on their products which are taking even longer to reach customers when they are purchased, and many local businesses and school districts that regularly replace their electronics are feeling the effects of the shortage firsthand.

“At this point, we’re waiting to replace our technology until we have to,” Reichling said. “If it’s needed, we’re getting it, but we’re being more strategic about it.”

Local school districts have experienced similar issues.

Coby Culbertson, chief technology officer for the Dubuque Community School District, said the school district is seeing seven- to 12-week delays on various monitors, docking stations and tablets it ordered for the new school year. Culbertson described the current volatility of electronics prices and the prolonged waiting times as unprecedented.

“We’ve had situations in the past, but nothing to the degree we are experiencing now,” Culbertson said. “We are trying to get out in front of it as best we can.”

The school district is currently waiting on the arrival of 250 tablets it purchased in July. Culbertson said the school district will continue to maintain its current equipment until the replacements are delivered.

Reichling said his company has begun turning to purchasing higher end model laptops in order to receive faster delivery of the equipment despite the increase in technology costs.

The problem isn’t just relegated to computers. Numerous other products that utilize computer chips in order to operate are experiencing similar shortages.

Dubuque-based trucking company Hirschbach Motor Lines Inc., ordered 1,400 new semi-tractor trailers in early 2021 but is still waiting on about 400 vehicles to be delivered.

“There are multiple onboard technologies, basically mini-computers based in these vehicles,” said Nick Forte, director of maintenance assets and facilities at Hirschbach. “They don’t have the computer chips to keep up with production of these vehicles.”

Forte explained that the delay in new semi-tractor trailers has created a substantial increase in maintenance costs for the company, which is now trying to maintain older vehicles. He added that those increased costs are being transferred to consumers for a variety of products, from gasoline to food.

The U.S. Department of Agriculture recorded that food prices increased by 3.4% in 2020, about 1% higher than the 20-year historical average of 2.4%. For 2021, it projects food prices will see between a 2.5-3.5% increase.

“That increased rate of shipping is going to raise prices,” Forte said. “This computer chip shortage is creating a supply issue, which is increasing the prices for a lot of products.”

U.S. President Joe Biden has pushed for the increase in manufacturing of more computer chips. In February, he directed White House staff to work with industry leaders on addressing computer chip shortages. Multiple proposed bills in Congress include funding for computer chip manufacturing and Biden’s $2 trillion infrastructure plan includes $50 billion for semiconductor production and research.

However, Forte said the computer chip shortage isn’t likely to let up until mid-2022, motivating his company to order replacement equipment almost a year in advance.

“We’ve already forecasted and are ordering replacement equipment that far out,” Forte said. “People do not realize the simplest things have microprocessors, and they are all contributing to this shortage.”