Founded: May 1953

Address: 109 Madison St. SE, Cascade, Iowa

Employees: 236 total at facilities in Cascade; Monticello, Iowa; Pleasantville, Iowa; and Tyler, Texas. The firm’s Cascade campus employs 176 people.

On the web: cascade-mfg-co.com

CASCADE, Iowa — During nearly 70 years, a Dubuque County business has retained its original purpose while expanding into manufacturing and information technology, all while maintaining family ties that stretch four generations.

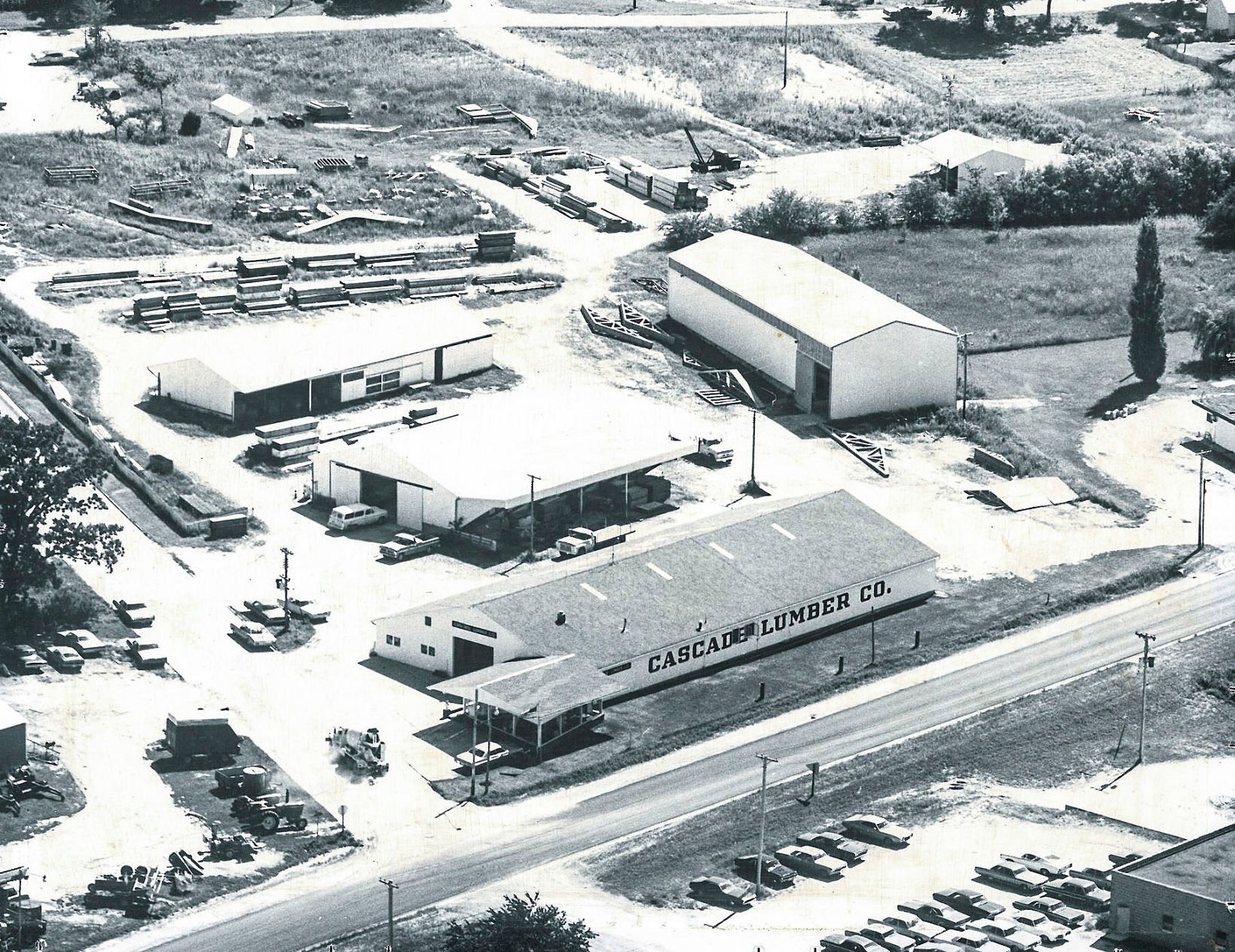

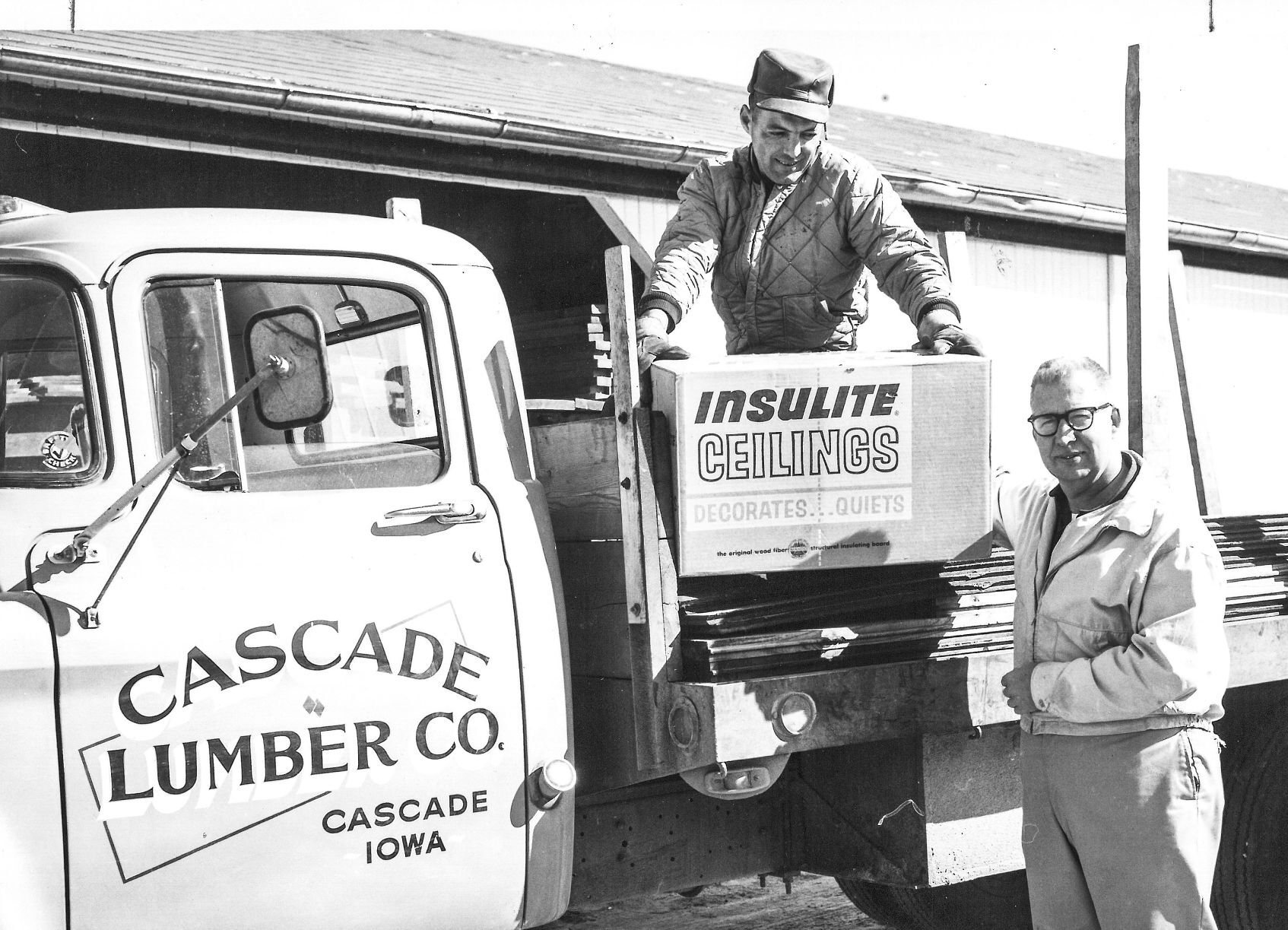

The late Ray Noonan Sr. founded Cascade Lumber Co. with his late wife, Mary, in May 1953. He was new to the lumber yard business but perceptively knew that construction needs would soar in the wake of World War II.

He also knew how to maintain and grow his fledgling lumber yard, said his son, John Noonan, vice president of the company’s retail unit.

“The secret is diversification,” John Noonan said. “He hated to lose a sale.”

That drive led to the evolution of the company, now better known as Cascade Manufacturing Co., first becoming a more-complete building supply retailer, then expanding into the manufacture of roof and floor trusses that form the framework of a variety of buildings, such as agricultural structures, senior centers, military facilities and homes.

Born in 1917 in Chicago, Ray Noonan Sr. visited a family farm in the Cascade area during his childhood. He graduated from St. Ambrose University in Davenport, Iowa, in 1939, and served in the U.S. Navy in World War II.

He worked in Manchester and Monticello before deciding to go into the lumber business in Cascade.

“He wanted to make some money doing practical things,” John Noonan said. “He always said there were three basic needs — food, shelter and clothing.”

Ray Noonan Sr. had sold turkeys earlier in his life and had no interest in selling clothes, so he turned his attention to serving the need for shelter. He and Mary opened a lumber yard on Cascade’s east side.

“Back then, he didn’t necessarily have all of the knowledge and all of the answers, so he surrounded himself with people who did,” said Tim Noonan, Ray Sr.’s grandson and current president of the company.

Among the company’s first employees were people with experience in the business, including Harry Thomas, Denny Leib, Ray Menge and Bob Takes.

“In 1953, when we opened up, lumber yards sold lumber, coal, cement, wire,” Tim Noonan said. “The hardware store sold nails and bolts. It made no sense (to Ray Sr.) that if he sold the lumber to a fellow he couldn’t sell him the stuff to put it together.”

That philosophy led the company to begin selling a variety of building supply materials.

Eventually, the company’s employees began to manufacture feed wagons, portable livestock buildings and other items to increase the profitability of the business.

“Dad had a vision for the diversification, and he would take somebody else’s idea and enhance it,” John Noonan said.

Ray Noonan Sr. belonged to a series of retail and other associations.

“Dad learned from other people,” John Noonan said. “He picked up a lot of their ideas.”

The company eventually ventured into manufacturing.

“We used to sell whole building packages. We sold the roof trusses, we’d sell the steel siding, the whole kit and caboodle,” Tim Noonan said. “Other lumber yards started to need the trusses because they were selling everything but the trusses. Rather than compete with those lumber yards, the decision was made to start a manufacturing division that would sell trusses for distribution through other lumber yards. That model continues today.”

That manufacturing unit grew much larger than the retail side of the business, Cascade Lumber Co., which continues to operate a store in Cascade.

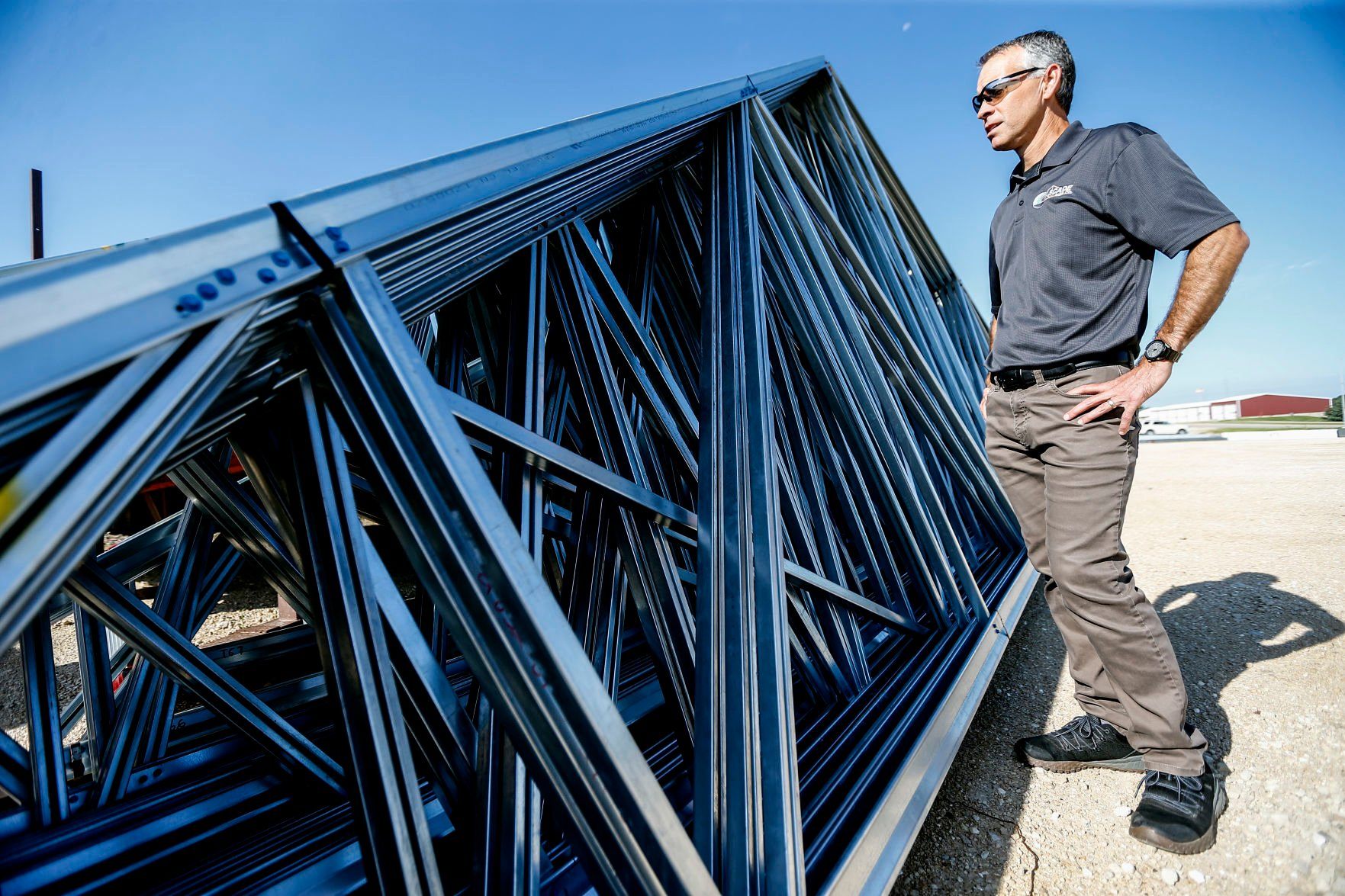

“About 35 years after the wood-truss manufacturing began, there came an alternative product called cold-form steel trusses — a light-grade, all-steel product that is a non-combustible alternative to wood,” Tim Noonan said.

The company manufactures and sells both types, despite facing a challenge 25 years ago that might have halted the firm’s progress.

A fire on Jan. 5, 1997, destroyed a 30,000-square-foot truss manufacturing complex that had been built in 1979. An 8,500-square-foot office building was a complete loss, too. Company management quickly turned its attention to rebuilding while maintaining as much of its production as it could.

“One of the keys there is, we had good insurance and a lot of good networking throughout the industry,” Tim Noonan said. “We were able to have other truss manufacturers take on orders for us so we could still fulfill customers’ needs while in the process of rebuilding. We were also operating out of what was at the time a mothballed truss plant in Eldridge, Iowa.”

The Cascade firm also received assistance from a truss plant in Maquoketa. That plant produced its trusses during the day, while Cascade would produce its trusses at night.

“When we emerged with the rebuilt plant, we were a two-plant operation with Cascade and Eldridge,” Tim Noonan said. “We ran a two-plant operation until 2005, when we opened (a plant) in Pleasantville, Iowa, about 30 minutes southeast of Des Moines.”

The company manufactures products in Cascade; Pleasantville; and Tyler, Texas.

“Today our market is the central time zone and the Southeast (United States) over to the panhandle of Florida,” Tim Noonan said. “We have shipped to 46 of the 48 continental U.S. states and eight countries in our steel-truss line.”

The company also operates a retail location as well as a wholly owned information technology subsidiary in Monticello.

Ray Noonan Sr. died in 2008 at age 90, but the firm remains rooted in the Noonan family.

“Ray Noonan Sr. worked with the company for 55 years. He stopped coming here a few months before he passed away,” John Noonan said.

Generations continue to guide the firm Ray Noonan Sr. founded.

“After Ray Sr., there were five siblings (his children),” said Tim Noonan, who is the son of one of those siblings, Ray Noonan Jr. “There are still two of those second-generation folks employed by the company — John Noonan and John Althoff. There are currently seven third-generation employees, and we have three fourth-generation family members working as seasonal employees in the truss plant this summer.”