Address: 951 Ninth Ave. NW, Farley, Iowa

Hours: 7 a.m. to 4:30 p.m. Monday to Friday

Phone: 563-744-3778

Website: https://tinyurl.com/xdh92ur8

FARLEY, Iowa — In 1994, Dennis Rauen opened Rauen Precision Machining out of his garage with his wife as his only employee.

It was a gamble for the Farley resident, who previously spent several years working in the tool and machining industry but wanted to start a business.

“I thought there was a need for a specialty shop in the area,” he said. “I knew there was a lot of local manufacturers that needed someone they could turn to.”

The gamble paid off. With every year, Rauen’s business slowly picked up speed, adding more customers and producing more tools and machine parts. In 2000, the business moved into a building in the Farley Industrial Center at 951 Ninth Ave. NW, and it only continued to grow from there.

Dennis Rauen is planning his retirement, though he has no official date for when he’ll leave the company. When he does eventually go, he will hand the business over to his son, Jason, who acts as vice president, along with his nephew and niece, John and Megan Dolphin, who serve as operations manager and secretary, respectively.

Even with the eventual change of ownership, Rauen is confident his business is an engine that will only continue to pick up speed.

“As far as we are concerned, we are going to keep expanding,” Rauen said. “There’s demand from customers, and we want to make sure they are happy.”

Rauen, who grew up on a farm in Dubuque County, developed an early passion for working with machines and was motivated to begin working in the tool and machine part industry after a friend offered to hire him.

“I liked making things with my hands,” Rauen said. “A friend of mine gave me an opportunity in the ’80s, and he taught me the business.”

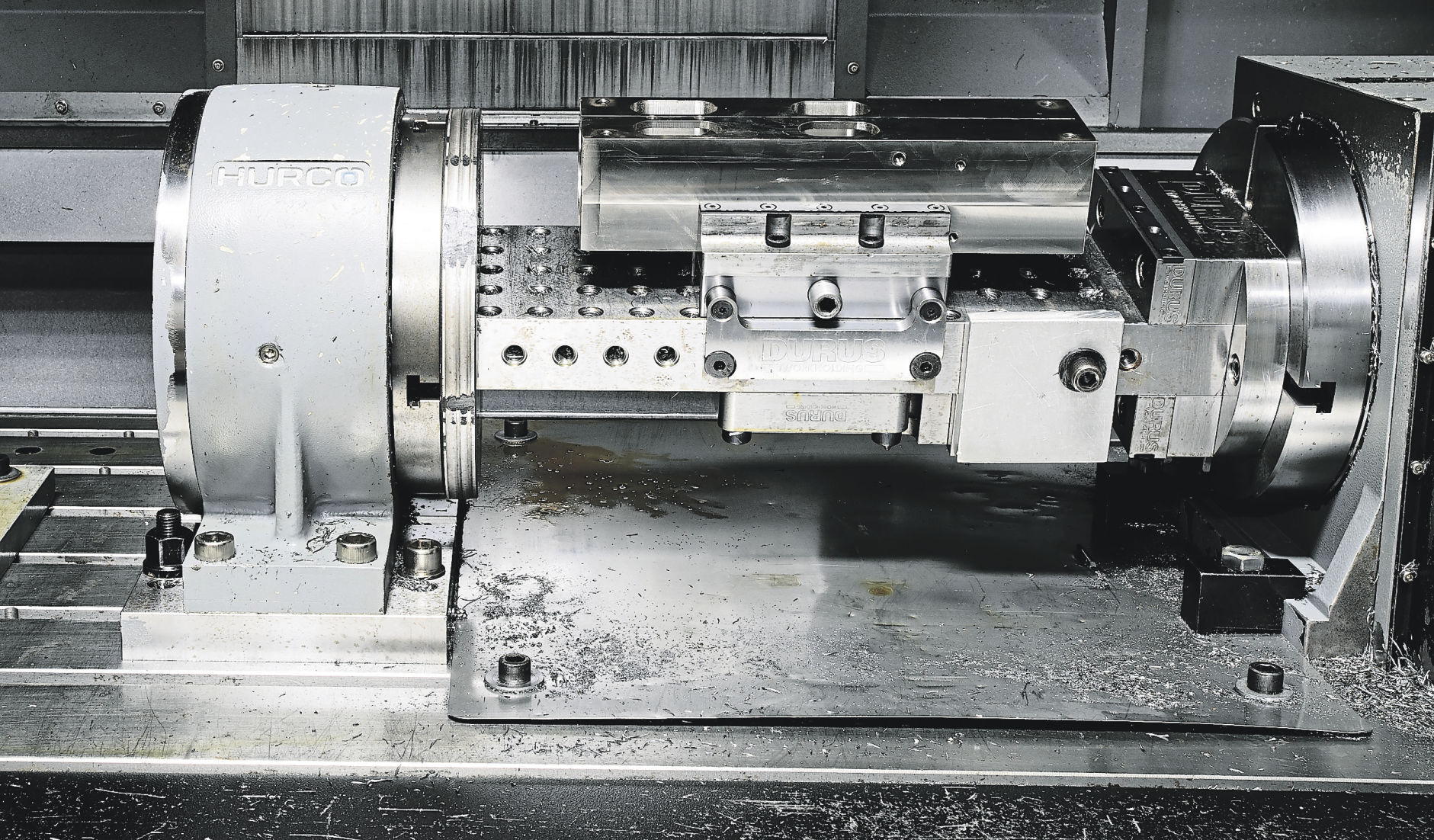

Rauen explained that his company prioritizes assisting manufacturers that are forced to halt production due to a faulty part or component. Those businesses then reach out to Rauen Precision Machining to make a replacement part as soon as possible to get the manufacturer operating again.

“We help repair machines and do whatever it takes to get things back on track,” Rauen said. “A lot of the time, someone will bring us a part and we will reverse engineer it and do it for them.”

The company has built a reputation off its capability to respond quickly and deliver a needed part for manufacturers who stand to lose money when their machines break down. Rauen said he prioritizes meeting deadlines and keeping in communication with manufacturers that need an emergency part replacement.

“When that happens, we call it a fire drill,” Rauen said. “A lot of times, it’s a shaft that goes bad or a part breaks and we’ll make a new one in time to get their production line going again.”

Along with part production and replacement, Rauen Precision Machining also provides services including powder coating and metal fabrication.

Rauen said his company uses its array of equipment to create prototypes for customers. Some products have included laser-cut trophies and fabricated railings.

Farley Mayor Jeff Simon said Rauen Precision Machining plays a major role in the local economy by ensuring that manufacturers can continue to operate.

“They definitely complement the overall economy of Farley,” Simon said. “They are always working with our other businesses here in town, making pieces and parts for other manufacturers.”

While the company’s clients mostly remain local, Simon said the company has seen steady growth throughout the years. Now with 25 employees, Rauen said the business recently purchased a neighboring building in order to expand its services.

“We have a pretty good customer base at this point,” Rauen said. “We’re very fortunate to be where we are at.”

However, Rauen’s business also faces stiff competition from both local and international companies. He noted that the COVID-19 pandemic helped his business by creating significantly longer waiting times for manufacturers that turned to overseas tool and part makers.

However, even when the effects of the pandemic subside, Rauen said he is confident in his family business’ continued future success.

“What I think is really important is developing trust,” he said. “They trust we will get the job done right at a fair price.”