In our monthly Made in the Tri-States feature, we highlight some of the area’s signature products. Watch for new installments each month. If you have a suggestion of a product for us to feature, send an email to jeff.montgomery@thmedia.com or ben.jacobson@thmedia.com.

CASCADE, Iowa — At Cascade Manufacturing Co., employees piece together the skeletons of structures that soon will spring to life.

The longtime Dubuque County business specializes in the construction of roof and floor trusses, which form the framework for a variety a soon-to-be-constructed buildings, ranging from banks and senior centers to military facilities and homes.

These structural systems must be strong enough to withstand significant weight and persevere through snowy and windy weather conditions.

The business itself is built upon a foundation of similar strength.

Cascade Manufacturing was founded more than 60 years ago. Through the decades, multiple generations of the Noonan family have served the business.

Pat Noonan, vice president of manufacturing, is part of the second generation to oversee operations.

“I have worked here all my life since grade school,” he said. “Prior to that, I was running around here playing with sawdust and blocks of wood.”

While family has remained a constant, the business model at the core of Cascade Manufacturing has continued to evolve.

The business now creates both wood and steel trusses, manufacturing products bound for work sites throughout the United States and beyond. And, it employs about 250 people across all its locations.

CHANGING THROUGH THE YEARS

The origins can be traced back to 1953, when Ray Noonan Sr. and his wife, Mary Noonan, opened a lumber yard in Cascade.

More than one dozen family members have become integral members of the business.

Pat Noonan is one of five siblings who have had a hand in the business.

His brother, John Noonan, sister, Mary Beth Althoff, and brother-in-law, John Althoff, continue to work at the business. Brothers Mike Noonan and Ray Noonan Jr. retired from the company last year.

Tim Noonan is among multiple family members who represent the third generation.

When he began working at Cascade Manufacturing, he was tasked with mowing the lawn and cleaning bathrooms. He worked his way up to operating a forklift.

Tim’s path to the business had some twists and turns.

After graduating from Loras College, he landed at McGraw-Hill and worked in the company’s IT department. In 2002, he had a change of heart and spoke with his father about joining the family business.

“I took a large leap of faith when I came here,” he said. “I was abandoning the line of study I had in college.”

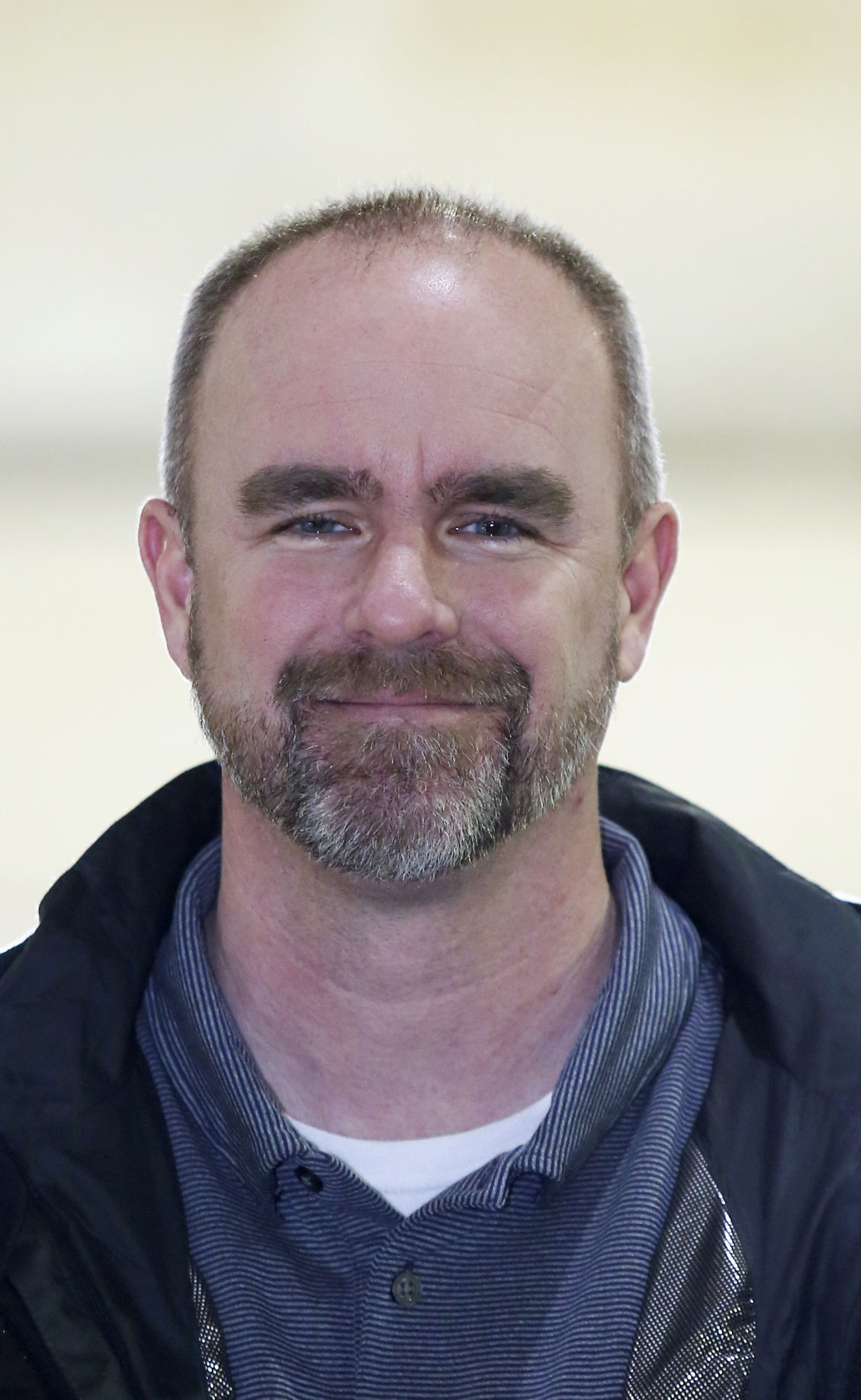

Tim Noonan became the president of Cascade Manufacturing in 2016.

Today he oversees a company with about 250 employees, including 175 in the tri-state area. This includes workers at Monticello Carpet & Interiors, a division of Cascade Manufacturing; and Infrastructure Technology Solutions, a subsidiary.

The business employs additional workers at factories in Pleasantville, Iowa, and Tyler, Texas.

VARIETY OF PRODUCTS

Employees in Cascade oversee the creation of truss systems from start to finish.

The process generally begins with a set of construction documents or house plans, which lay out the general geometry of a roof. Such outlines leave plenty of room for innovation.

“It is up to us to go under the hood and create the structural skeleton of that roof,” said Pat Noonan.

Noonan noted that roof trusses influence the appearance of a home, giving the top of a structure its unique pitches and angles. These trusses have become increasingly complex and varied.

Cascade Manufacturing employees create the designs for trusses, load the drawings into a computer and convey them to the shop.

Saws then cut the pieces to the specifications and send them to computer-operated assembly tables. Pieces of the truss are pinned together with metal connector plates, which are crushed into the lumber by a series of “presses.” They then are loaded on to roller trailers and delivered to a job site.

The campus includes two large manufacturing structures, both of which span approximately 30,000 square feet.

In one building, employees oversee construction of wood trusses, a process that is highly automated.

“With the advent of computerization in the shop, that has been really helpful on cutting down on the time it takes to build an order,” Pat Noonan said.

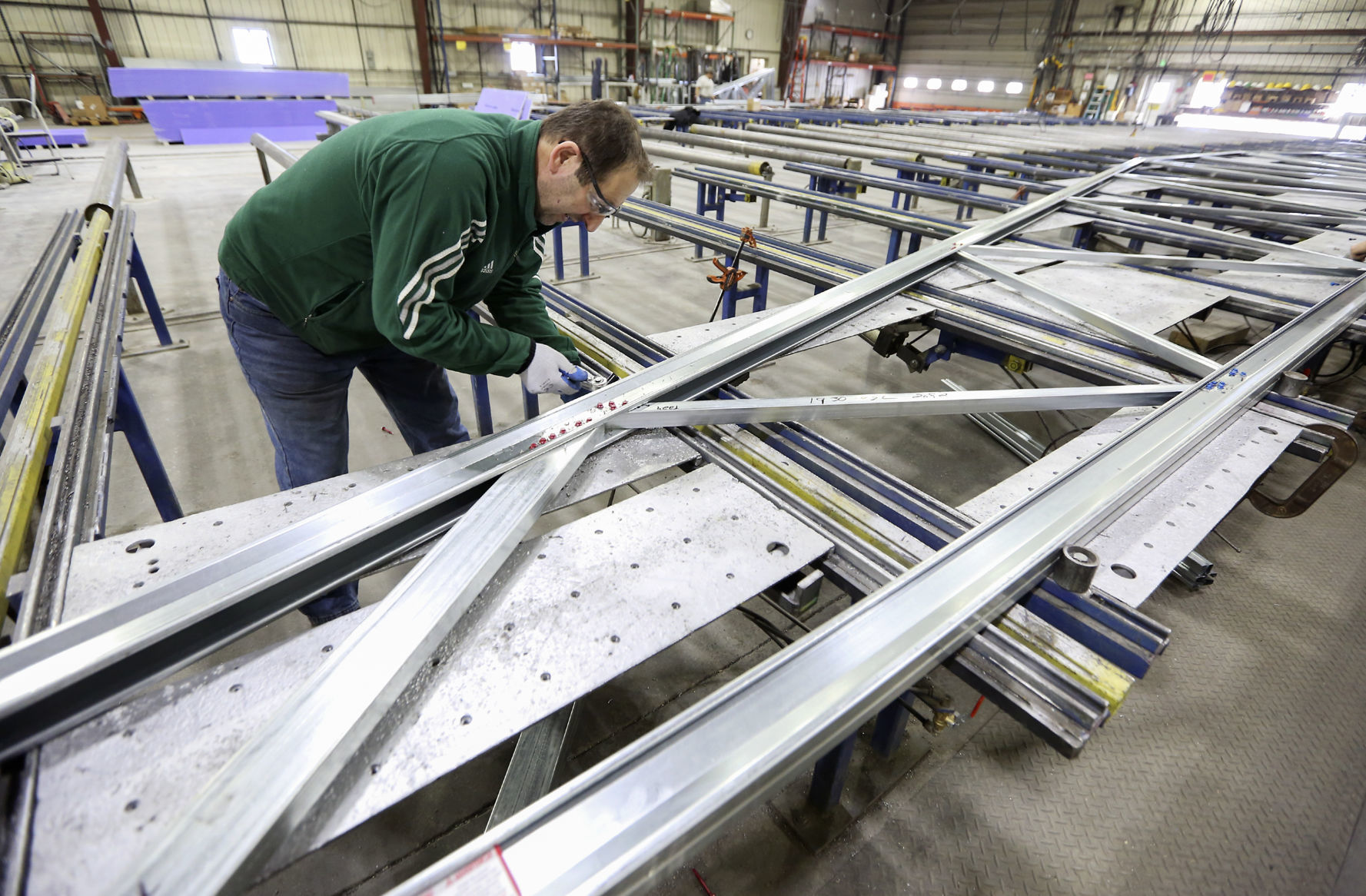

The other building is dedicated to the creation of steel trusses, a line of business the company embraced about two decades ago.

Steel truss manufacturing is more of a manual process, largely because that area of expertise is so rare.

Workers cut materials on a band saw and screw them together by hand.

Whether they are making steel or wood trusses, employees rarely tackle a cookie-cutter project.

Every truss undertaking is unique.

“Everything is custom built,” said Pat. “There are no stock-type items that we build.”

EYE TOWARD THE FUTURE

Tim Noonan believes that the steel truss component positions the business for major growth in the future.

The company has established a vast footprint in that market.

“On the wood truss side, we mainly serve Iowa, Illinois and Wisconsin,” Tim said. “We are a national player in the steel truss market. We have served 40 different states and six countries, and I think we can grow that arm of the business.”

An ongoing labor shortage could serve as a boon to the Noonans’ business.

With construction companies struggling to attract workers, the demand for pre-fabricated structures — such as trusses — has soared. These items can be assembled off-site and delivered to a construction job intact, cutting down on the labor that construction companies need to hire to complete a project.

Hoping to seize on that opportunity, Cascade Manufacturing has introduced new products such as pre-fabricated wall frames.

Tim Noonan acknowledged that the labor shortage works both ways.

At Cascade Manufacturing, company leaders have taken steps to make sure they don’t lose their valuable employees. In recent years, the company has added vision insurance to workers’ benefits. Officials also introduced a new paid holiday, allowing employees to take the Friday after Thanksgiving off work.

Scott Wagner, director of operations, said workers appreciate the sense of family that exists at the business.

“We are here to work first, but you also care about the person you are working next to,” he said. “It is not just lip service. It is something you see every day, and it is led by the (Noonan) family’s example.”