In our monthly Made in the Tri-States feature, we’ll go behind the-scenes of some of the area’s signature products. Watch for new installments the first Sunday of each month. And if you’ve got an idea for us to feature, send an email to jeff.montgomery@thmedia.com or ben. jacobson@thmedia.com.

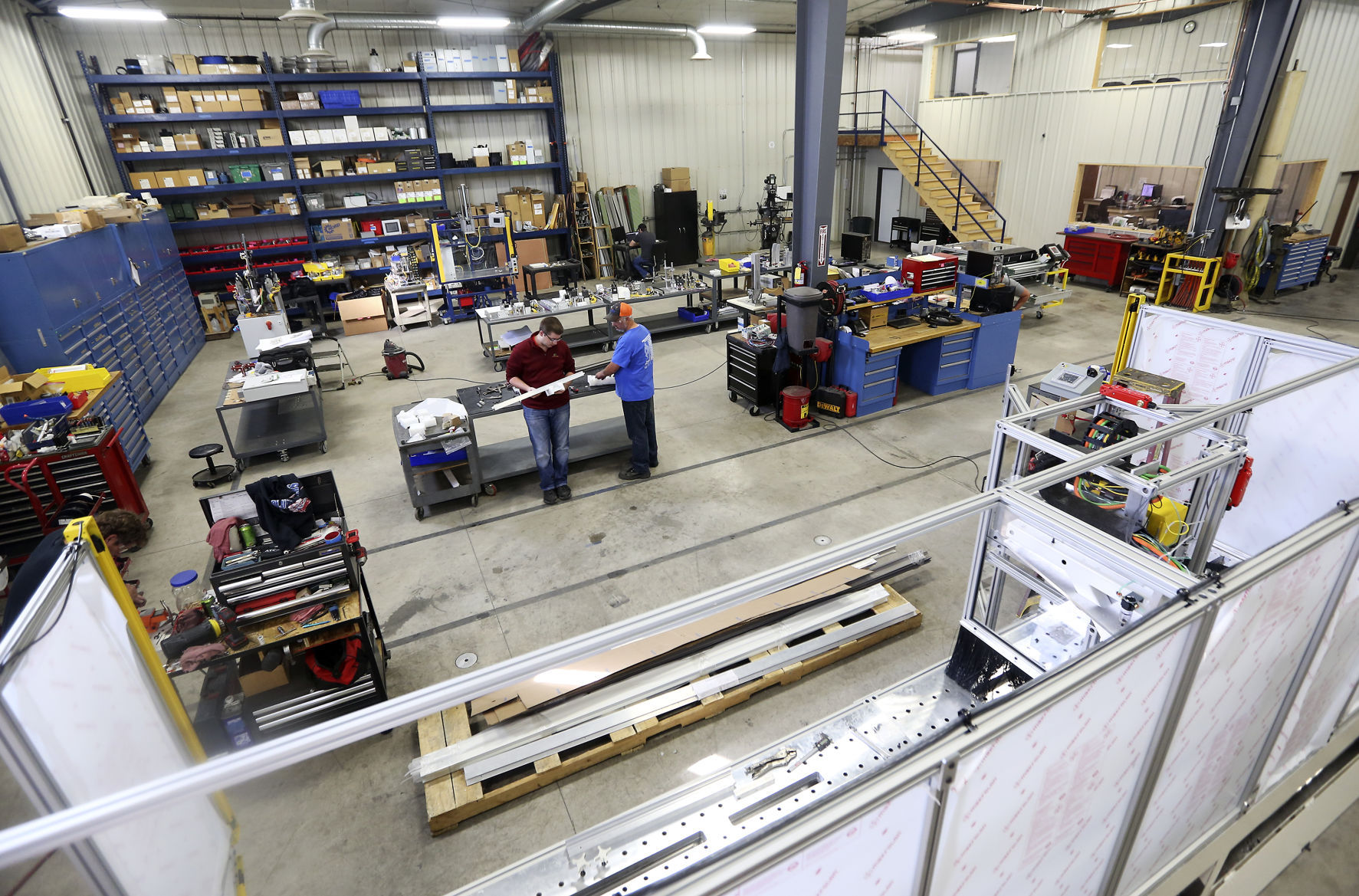

LANCASTER, Wis. — The products made at Lancaster Machine & Tool rarely, if ever, make it to the shelves of a retail store or a consumer’s household.

During the past two decades, however, the business has carved out a large customer base by appealing to a specific kind of client.

“We are a manufacturer that makes things for other manufacturers,” said owner Mark Schwab. “We create parts and we automate processes that make it possible for other businesses to make their products.”

Lancaster Machine & Tool, located at 1900 Industrial Park Road, counts A.Y. McDonald, General Motors, Ford and Harley-Davidson among its major clients.

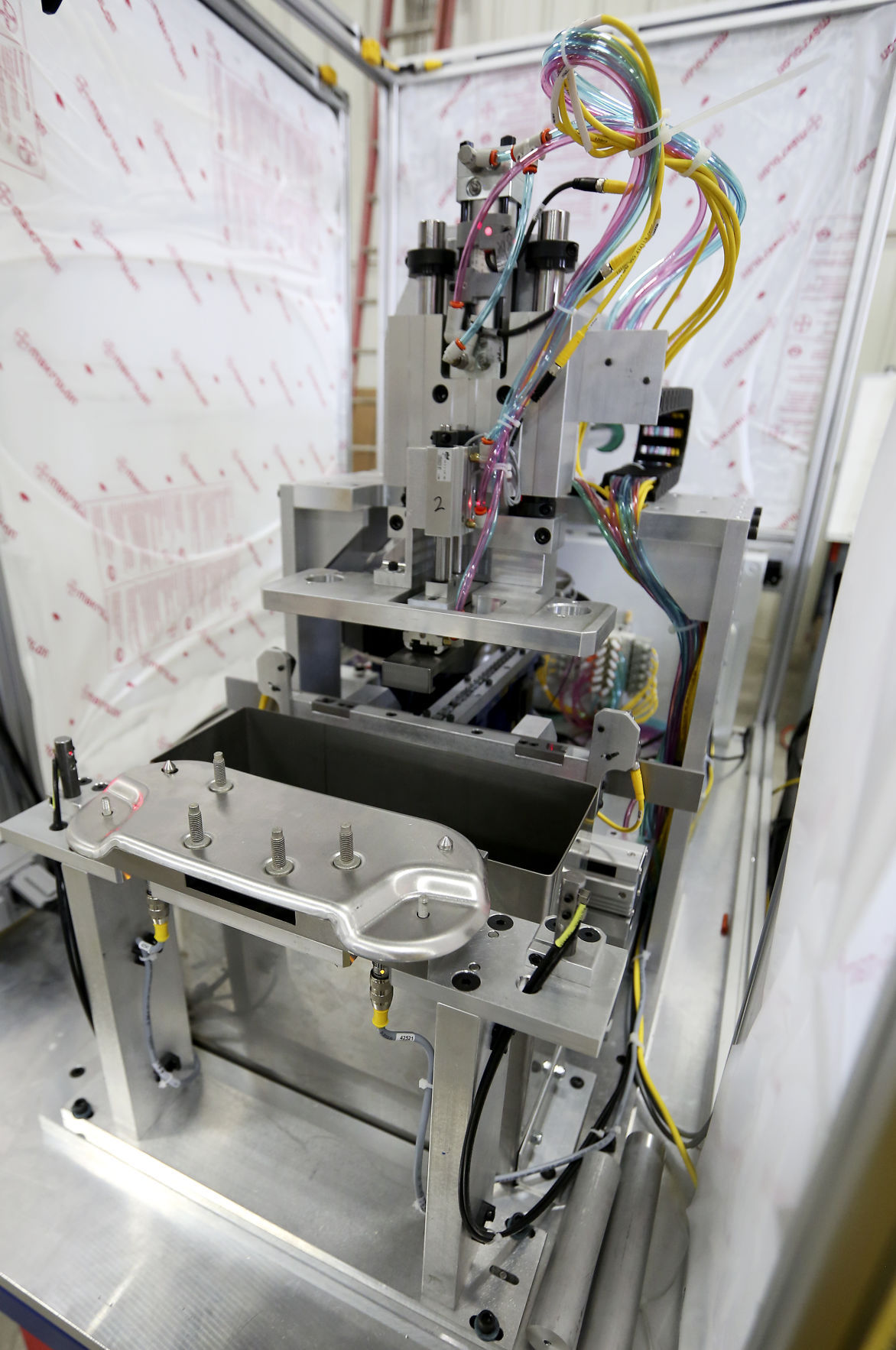

Schwab said the company creates a wide range of specialty parts, including fixtures that serve as key components of many manufacturing processes. Fixtures are used to secure parts in a specific location during manufacturing work, he said.

In addition to making these products, Lancaster Machine & Tool engineers items that clients need.

Schwab said this is a far cry from what the company did when it was founded in 1995.

“It has all changed so much,” he recalled. “Back when we began, the manufacturers did their own design work, gave me a blueprint and I would machine the parts. Now we design a part for them and create the part. We take care of every step in the process.”

GROWING COMPANY

As Lancaster Machine & Tool has expanded its capabilities, the company has diversified its workforce.

Schwab said the business now employs mechanical engineers, machinists, welders, fabricators and PLC (Programmable Logic Controller) programmers.

The expansion of the company’s duties and its growing client base have resulted in a slow, steady pattern of workforce growth.

“Back when we started, it was just me,” Schwab said. “Now we are up to 27 employees.”

The steady growth of Lancaster Machine & Tool has been evident in its facility as well.

Schwab said that the company started operating out of a rented building in the city’s downtown in 1995. Four years later, the business moved to its current location.

During the past 18 years, Schwab has expanded the facility four times. He said a fifth expansion could be on the horizon, potentially allowing the business to add to its workforce.

Ron Brisbois, executive director of Grant County Economic Development Corp., said this kind of growth is an example of how the county’s economy can thrive.

“That is the type of growth we are hoping to see,” Brisbois said. “You are not going to see a business come in (to Grant County) and create 150 jobs all at once. Instead, this area will see slow and steady growth, (with businesses) adding a few people at a time and continuing to expand. This is a company that treats people well, has low turnover rates and is achieving economic growth that way.”

FILLING THE NEED

Schwab believes recent changes in the manufacturing industry, as well as the local economy, could position his company for more growth in the future.

“A lot of manufacturers these days are expanding, but they cannot find the help,” Schwab said. “So what they want to do is automate a lot of their processes.”

Through the years, Lancaster Machine & Tool has evolved into the kind of company that can meet that complex need. Schwab said the company’s employees take pride in being a “one-stop shop,” where workers can handle every step of the process.

As companies seek increased automation, Schwab and his team are capable of designing a new machine and bringing that item to life.

Schwab described his company as a “job shop,” noting that the nature of the work keeps things interesting for him and his team.

“We are always making something different every time,” Schwab noted. “We don’t mass produce any one product.”

Brisbois noted that the company’s diversity isn’t limited to its products. In his view, Lancaster Machine & Tool has positioned itself for long-term success by amassing a wide range of customers.

“They aren’t limited to one industry and they’ve built up a diverse base of clients,” Brisbois said. “A company is stronger when they don’t put all their eggs in one basket.”

Brisbois said the success of Lancaster Machine & Tool also has strengthened the businesses around it. For example, Alternative Recycling in Lancaster uses scrap metal produced by Schwab’s business.

“Several local businesses work directly with Lancaster Machine & Tool and that is a big deal,” Brisbois said. “With a company like that, it is like throwing a pebble in a pond. There are waves of economic impact.”