About three decades ago, Mike Weitz landed his first gig at the family sign company.

“My job was going down and sweeping up the shop,” he recalled. “There was lots of sawdust and dirt.”

Today, Weitz reports to work in a far different capacity.

He serves as the president and owner of Weitz Sign Co., and represents the second generation of a business that recently celebrated its 36th anniversary.

The business employs 20 workers and serves a wide variety of customers. While Weitz Sign Co. has made product for clients across the country, the majority of its customers reside in Iowa, Wisconsin, Illinois, Ohio and Michigan.

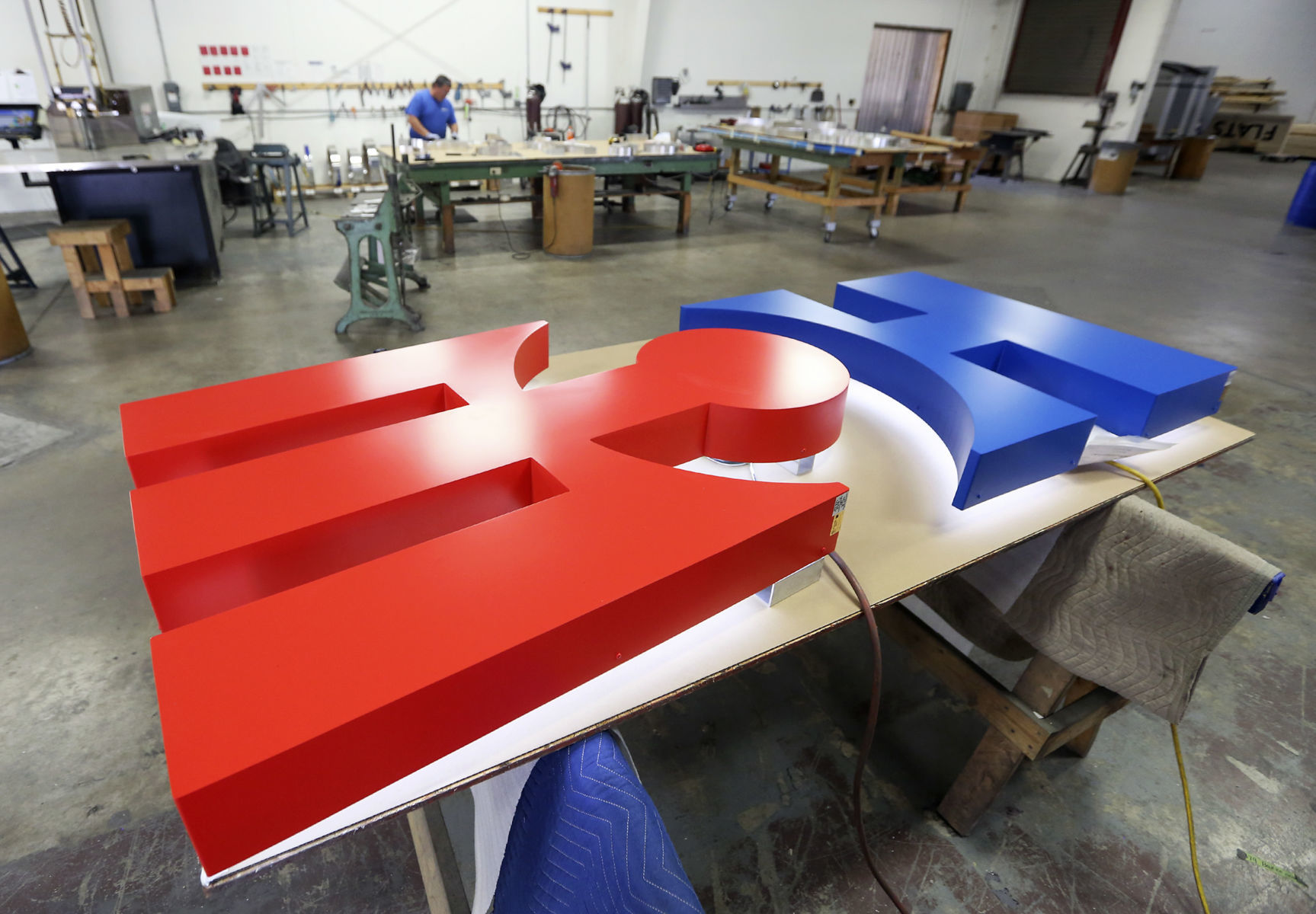

A walk through the expansive facility at 2400 Kerper Blvd. reveals the breadth and diversity of products the company has created.

Large letters, waiting for shipment, will one day spell out a company’s presence to passersby. Hulking pylon signs will soon sit outside shopping centers or industrial parks, displaying the variety of tenants that reside within.

A small number of neon signs — less commonplace in today’s market but popular among some customers — also are displayed on the factory floor.

Such variety is an essential ingredient for Weitz Sign Co., according to its president.

“We don’t build 1,000 (copies) of the same sign,” he said. “We do a lot of custom work. Everything we do is meant to meet the needs of that particular customer.”

LENGTHY HISTORY

The company was founded by Mike’s parents, Larry and Marikka Weitz, in July 1983.

Larry had spent the prior decade working for Frank Hardie Advertising. When the opportunity arose to purchase the “on-premise sign” division of that company, he jumped at the opportunity.

The business was initially known as Signgraphics and operated out of a facility on Elm Street. Five years later, the company moved to its current location at 2400 Kerper Boulevard.

Weitz Sign Co. once split its time between retail and wholesale signage.

In 2003, the company sold the retail portion of its business to Lange Sign Group.

Weitz Sign Co. focuses strictly on the wholesale end of operations. The company does not have a sales force that deals directly with end-users, nor does it create the conceptual designs for its signs.

The focus is on manufacturing.

“We create on-premise signs,” Weitz explained. “That means we build the signs and letters that you see on buildings, we build the large pylon signs out front, and some of the smaller, directional signs you see on a property.”

The exact process varies depending with each product, but Weitz said the creation of most signs follows a general formula.

Workers cut the various metal and plastic parts to the proper dimensions on a router table.

In many cases — particularly when letters must be shaped — the materials are bent to the desired shape. Weitz said this usually is done by a machine, but occasionally is carried out by hand.

Employees then weld the different portions of the sign together and, in many instances, add lighting features. Finally, workers carry out the “finishing” of the sign, which often includes painting or sanding.

Weitz said today’s clients are searching for something that sets their signage apart. In some cases, this means eye-catching color schemes; in others, it means a distinctive curvature or shape.

“They don’t want a plain, old square sign,” Weitz said. “They are looking for some dimension, some uniqueness to identify the brand.”

About four years ago, the business completed a 5,000-square-foot expansion to its facility. Weitz said they took over a portion of the existing facility that previously was occupied by another tenant.

“We were really busy and just so cramped,” he recalled. “That (expansion) definitely gave us more breathing room and allowed us to be more efficient.”

FAMILY BONDS

More than three decades after starting the business, Larry Weitz marvels at the intensive process that brings the signs to life.

“People don’t pay much attention to signs. They don’t know what goes into it,” he said. “We build everything from the ground up. And when you are finished, you get to say, ‘Wow, that looks really good.’ It’s a great feeling. I’ve never lost it — that feeling of seeing a finished product.”

Even though Mike has taken the reins, his parents play a prominent role at the company.

Marikka works a few days per week as an accountant and bookkeeper.

Larry, meanwhile, takes care of the pricing and interacts with customers. The company founder said he has “cut back” his hours to between 30 and 40 per week, a far cry from the 60-hour work weeks he endured as the company owner.

“I have no other life,” he said with a hearty laugh. “This business is my life and I enjoy it. If I didn’t enjoy it, I wouldn’t still be doing it.”

Seeing his son take over is an added bonus.

“He’s basically been running it for a lot of years,” he said. “I am blessed with smart children. I think they inherited it from their mother. I am proud of my son Steve (who does not work with the company) and I am proud of Mike. He has done a great job with the company.”