Address: 100 S. Commerce St., Galena, Ill.

Founded in: 1912.

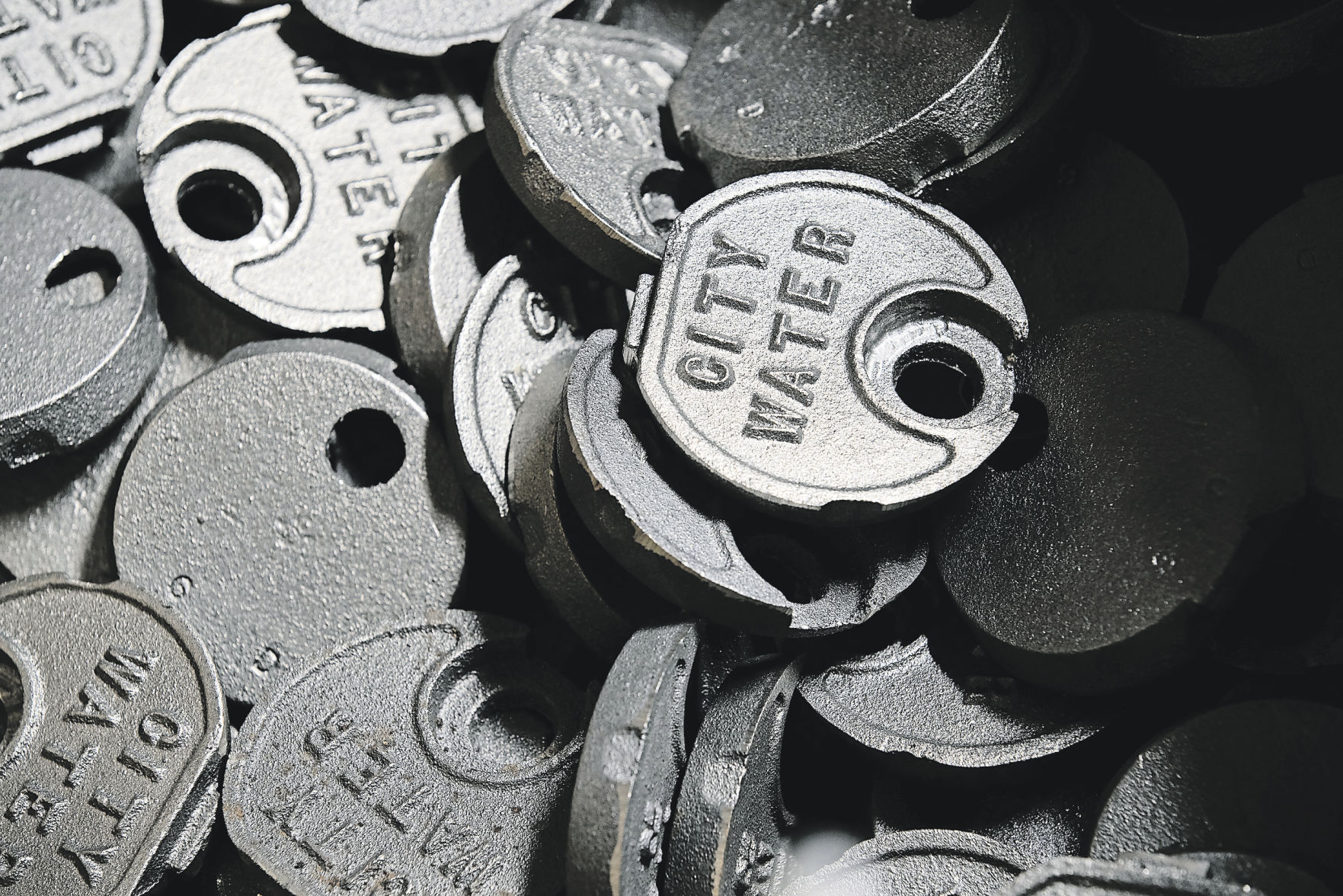

Specializes in: Gray iron casting.

Phone: 815-777-0242.

Online: lemfco.com.

In our monthly Made in the Tri-States feature, we highlight some of the area’s signature products.

Watch for new installments on the first Sunday of each month. If you have a suggestion of a product or company for us to feature, send an email to jeff.montgomery@thmedia.com.

GALENA, Ill. — At various points in their lives, Desiree and John Einsweiler contemplated a career that didn’t involve their family’s longtime business.

But the siblings ultimately felt themselves drawn back to the foundry — and they now represent the fifth generation to lead Lemfco.

“I basically grew up working here,” Desiree said. “I feel like this business is home. To come back and carry on that tradition, it means more to me than I can even express.”

Desiree and John bought into the family business five years ago. Desiree serves as the company’s president, while John holds the position of vice president.

They now lead a company that was started by their great-great-grandparents and which has called Galena home since 1912.

Located at 100 S. Commerce St. since its first day, Lemfco is a foundry that primarily creates small to medium runs of gray iron castings for customers, ranging from the agriculture and food processing industries to the petroleum and natural gas sectors.

Their products ultimately make their way to customers throughout the nation — and the world.

“About 70% of our customers are in the Midwest, but we have clients in Texas and North Carolina and a number of other states … and some of them export the final products throughout the world,” Desiree said.

Lemfco operates out of what is now a 40,000-square-foot factory that connects to a 40,000-square-foot warehouse. But it used to be a much smaller, simpler place.

“We’ve been in the same location the whole time,” Desiree said proudly. “We started in a tiny corner of where the plant is now. Through the years, we’ve expanded and added on and grown into what we have now.”

The business takes scrap metal, melts it down into a liquid form then remakes it into a useful product. It’s a process that is more fascinating than John once realized.

After graduating from high school, he left town to attend college and study music performance and mathematics. He recalls having conversations with classmates about the family business back at home.

Seeing the operation freshly through their eyes, he gained a new perspective about it.

“I didn’t realize how fascinating this work was,” he said. “I had to step back and realize that I always took for granted what we did. I didn’t realize when I left what a unique business it was or what a unique childhood I had.”

For John, being around the factory brings back a host of childhood memories.

“When I was a little kid, I used to come here and play with the air gun nozzle,” he said. “I’d blow dirt around the floor. I’d go up to a worker and blow the hat right off of their head.”

Shortly after graduating from college, John returned to Galena for what he thought would be a brief visit. His father, Dirk, who then co-owned Lemfco, was having a hip replacement procedure and John planned to briefly keep an eye on business operations.

It was around then that he realized his uncles — Dirk’s brothers — were contemplating retirement and interested in selling off their portion of the family business.

John decided to come back to the family enterprise and encouraged his sister to do the same.

Desiree said the decision was an easy one.

“When the opportunity arose, it was a no-brainer,” she said. “As a child, this is what I always wanted to do.”

Located in a city dominated by the tourism industry, where restaurants and gift shops abound, the Einsweilers realize that their manufacturing operation represents something different.

That has been abundantly clear during the past year, as COVID-19 shut down much of Galena’s economy for multiple weeks.

“During the pandemic when things were shut down, we kept running and we made essential products — things that had to be distributed,” Desiree recalled.

Rick Zillig, director of manufacturing at Morrison Bros. in Dubuque, said his company has long enjoyed a good business relationship with Lemfco.

“We’ve known each other and worked with each other for the last three generations,” Zillig said.

Lemfco provides iron castings that are used by Morrison Bros., Zillig said. He noted that many companies have turned to overseas partners to acquire such materials — something that Morrison Bros. has avoided through the years.

“Our relationship with Lemfco has gone a long way in keeping our iron casting production domestic and within our local region,” he said.

Lemfco employs 18 people, many of whom have been with the company for two or three decades.

And while the company sometimes prides itself on what hasn’t changed through the years, John emphasized that he is eager to continue modernizing the operations on Commerce Street.

He noted that the company recently began doing runs of ductile iron, marking a noteworthy point of diversification for a company that has long focused on gray iron castings.

John also views technological upgrades as a key to the company’s progression in the years ahead.

“I want to put everything that we earn back into the company,” he said. “The goal is to be able to pour the best castings as quickly as possible, and I think the key to that is automation. It makes the job easier for the guys on the floor, and there have been amazing advances in foundry technology in the last 10 to 15 years.”