In our monthly Made in the Tri-States feature, we highlight some of the area’s signature products. Watch for new installments on the first Sunday of each month. If you have a suggestion of a product for us to feature, send an email to jeff.montgomery@thmedia.com or ben.jacobson@thmedia.com.

For more information about Buncombe, visit sewandscreen.biz or call 608-744-2516.

HAZEL GREEN, Wis. — For more than two decades, Buncombe has been a part of the Gushulak family’s fabric.

Ginnie and Mike Gushulak formed the embroidery and screen-printing business out of their home in 1997. The enterprise was initially a side job but quickly evolved into a livelihood.

Today, Mike Gushulak believes his life is firmly intertwined with the family business.

“When you are self-employed, it is different than working for somebody,” he said. “You are basically living it. The business is part of you.”

Located at 4000 Leadmine St. in Hazel Green, Buncombe creates everything from school T-shirts to corporate signage.

Mike said the customer base is as varied as the products themselves.

“We work with a lot of colleges, a lot of schools and we also have a number of corporate customers,” he said. “Our customers are mostly right here in the tri-state area.”

BRINGING PRODUCTS TO LIFE

Ever since its formation, Buncombe has remained a family business in the truest sense.

Three of the five people who work there today are members of the Gushulak family.

When a customer wants Buncombe to create a product, the process often begins with Mike and Ginnie’s daughter, Julie Euler.

Euler, the company’s graphic designer, converses with the customers to get a feel for the product they envision.

“Usually, they give me an idea of what they want and then I just run with it,” Euler said.

Once Euler has created a design, others at Buncombe bring it to fruition.

Ginnie oversees the embroidery process.

She noted that Buncombe has significantly increased its capacity through the years. The company started with a single-head embroidery machine and now has both a single-head and a six-head machine.

The embroidery process is mostly automated these days, but oversight of the machinery is a necessity. Ginnie has become an expert and makes sure nothing goes awry.

The screen-printing process, meanwhile, is largely overseen by employee Brittney Foldenauer. Buncombe uses a manual and automated press to create its screen-printed products.

Mike said screen printing and embroidery go hand-in-hand, noting that both processes serve as ways of “embellishing garments.” He has noticed that different customers have different preferences.

“What I have seen is that embroidery is more popular for the corporate clients,” he said. “Screen printing is preferred by the local schools and local teams.”

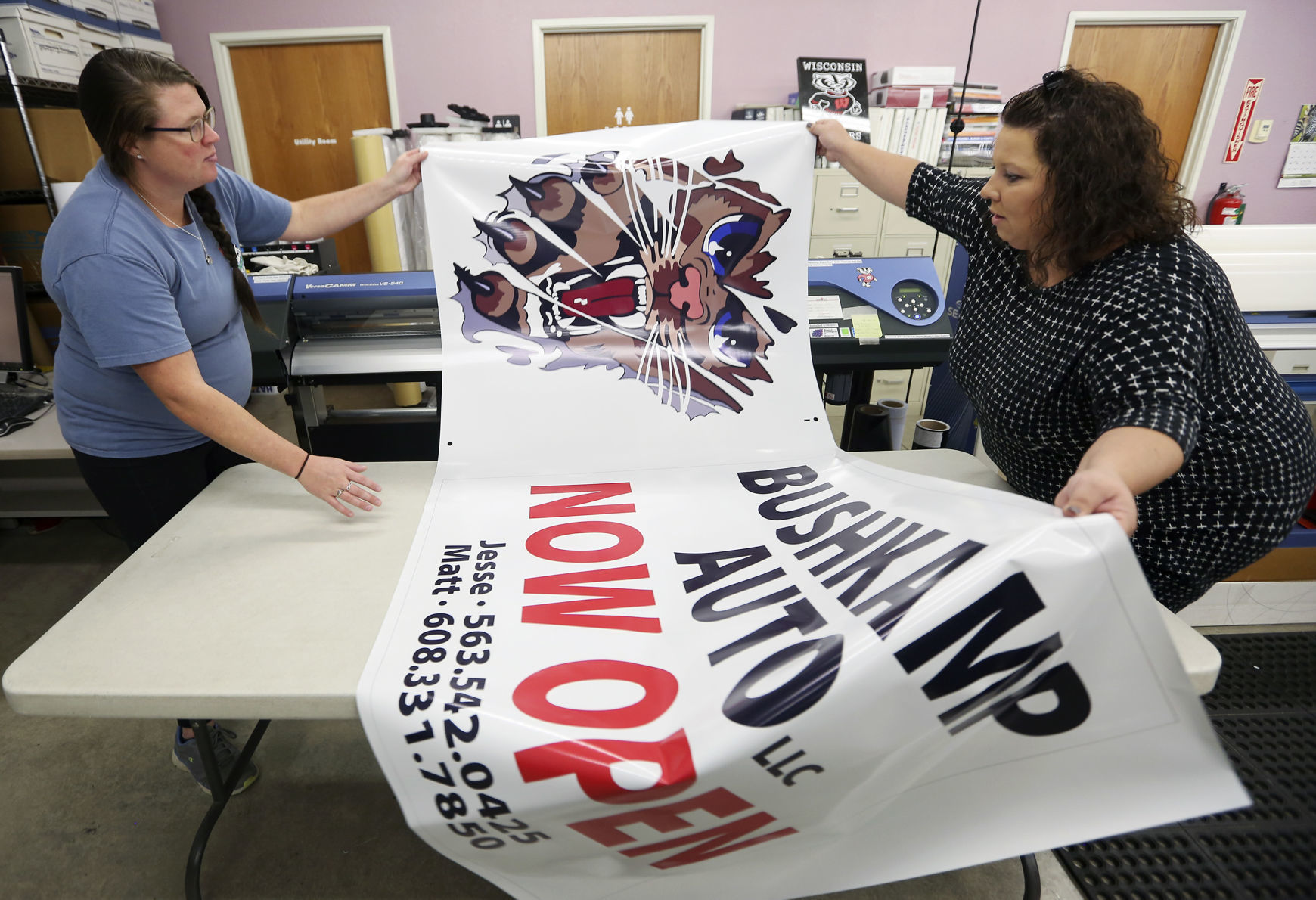

Buncombe also conducts digital printing and creates vinyl graphics within its Hazel Green facility. Digital printing is popular among corporate customers hoping to create banners or signage.

The vinyl graphics, meanwhile, often decorate the exterior of vehicles. Euler noted that Buncombe recently designed a new logo appearing on trucks for Scales Mound Fire District in Illinois.

She always enjoys seeing the finished product, especially outside of Buncombe’s doors.

“It is fascinating,” she said. “You will be out and about and look at a sign, or see someone wearing a shirt or a hoodie, and you’ll think, ‘I made that.’ It makes me feel good.”

HUMBLE BEGINNINGS

Buncombe’s origins trace back to the late 1990s, when Ginnie’s frustrations with the working world compelled her to create her own solution.

“I had worked for 20 years (in two different positions) and realized I had nothing to show for it,” she said.

Mike and Ginnie concluded that the best solution was to “create their own jobs” by starting a business.

They launched Buncombe out of their basement in 1997.

The husband-and-wife duo quickly realized they possessed complimentary skill sets.

“I figured he is good with numbers and I can run the machines,” Ginnie said. “We took the best of what we both could do and combined it together. It just fit.”

One year later, they added screen printing to their offerings. They put the new equipment in their garage.

About five years after starting Buncombe, the Gushulaks decided their growing business was too big for the family home.

In 2003, the family commissioned construction of a 4,000-square-foot building. They continue to reside in the property today.

Mike noted that Buncombe’s 22-year run has not always been seamless. About a decade ago, the Great Recession led to a decline in orders and forced the Gushulaks to tighten their belts.

Today, Mike looks back on that time and sees it as a positive learning experience.

“It made me a better business person,” he said. “It taught be how to follow a budget and watch all my costs.”

The staff at Buncombe also has learned to appreciate one another.

With just five people staffing the business, the workers are acutely aware that each team member is essential to the operation. The familial relationships only enhance the connection among employees.

“There are some times when it does get a little stressful, because everyone has their own personalities,” Ginnie said. “You just have to remember that everyone has their own knowledge in their own departments. The key is you have to respect each other.”